From electric vehicles to common portable electronic products, there is a huge demand for batteries with high storage capacity and fast charging speed. A team comprising researchers from City University of Hong Kong (CityU) has developed an anode material for lithium batteries with fast charging and discharging capabilities, which may significantly shorten the charging time for electric vehicles from half-hour to just three to six minutes. Moreover, the material showed excellent durability with a high capacity retention of 98.7% after 500 cycles of charging and discharging. Researchers believed that their research results have a high market value.

This new lithium battery material with fast charging and discharging capabilities was successfully developed by the research team of Dr Qi Liu, Assistant Professor of CityU’s Department of Physics, in collaboration with scientists from the mainland China. Their findings were published in the scientific journal Nature Communications, titled “Boosting fast energy storage by synergistic engineering of carbon and deficiency”.

Conductivity improved by encapsulating the grains with carbon

“The key to fast charging of materials lies in the rapid electron transportation (means high conductivity) and efficient diffusion of lithium ions. The new material we have developed focused on these two aspects,” Dr Liu first explained the rationale behind fast charging.

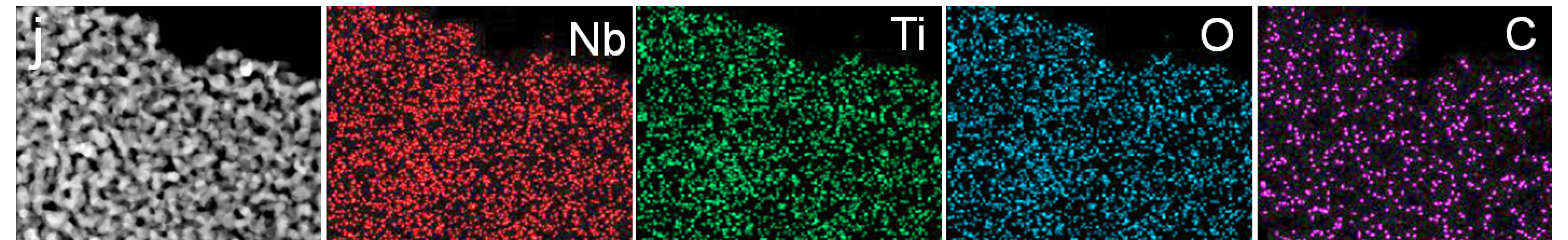

With the controllable low-temperature carbon-coating technique, the grains of the new material the research team developed, namely Ti2Nb10O29 (TNO), were uniformly encapsulated with carbon shells. The thickness of the carbon shell was adjustable and the team carried out experiments on this. It was found that grains encapsulated with a carbon coat of 3nm in thickness exhibited the best performance.

TNO charging speed faster than graphite lithium battery materials

Although the grains were encapsulated by carbon, the structure of TNO remained the same. Also, the team introduced oxygen deficiencies in the TNO when fabricated. “Oxygen deficiencies can increase the electrical conductivity of the material, therefore charging can be speedy,” Dr Liu explained. When the conductivity increases, electrons will transfer rapidly and generate heat energy. Dr Liu reassured that the related heat energy is controllable and would not affect the safety of TNO. Experiment results also showed that lithium ions were easier to migrate in TNO with oxygen deficiencies.

Because of the rapid electrons transfer and diffusion of lithium ions, TNO encapsulated by carbon shell of 3 nm in thickness possessed fast charging and discharging capabilities. “This material can reach a high capacity of 197 mAh g−1 after charging for just three minutes. This speed is faster than the commercialized graphite lithium battery materials,” Dr Liu further elaborated.

Lithium batteries are mainly composed of four parts: a cathode (positive electrode), an anode (negative electrode), electrolyte and separator, and electricity is generated through electrochemical reactions. Graphite is one of the commercialised anode materials for lithium batteries. “But fast charging is not possible for graphite. In fact, so far no anode materials in the market have achieved fast charging. The method we fabricated TNO, an anode material with fast charging capability, and the mechanism behind can be considered a breakthrough for the development of advanced battery materials,” concluded Dr Liu. He believed that the results of this research have great market value for application.

Great market potential in fast charging anode materials for lithium batteries

Dr Liu pointed out that even when charged slowly, in theory, TNO could reach a high capacity of over 400 mAh g−1, which is also higher than graphite. “If the carbon-coated TNO is used as the battery's anode material for electric vehicles, the charging time is expected to be significantly shortened from half-hour to only about three to six minutes,” elaborated Dr Liu.

More importantly, TNO encapsulated by carbon shell of 3 nm in thickness have exhibited long-term durability. It achieved a stable and high capacity retention of 98.7% after 500 cycles of charging and discharging, while TNO without a carbon shell only showed a capacity retention of 85.9% over 500 cycles.

Dr Liu suggested that the capability of fast charging is the greatest advantage of carbon-coated TNO. Although it is more expensive than titanium dioxide (TiO2), another relatively common battery material, TNO’s structure is more stable than titanium dioxide. He also pointed out that the engineering of carbon coating and oxygen deficiency is applicable to other anode materials consisting of metal oxides. Moreover, he described it as a ground-breaking method in the boundary carbon design of composite materials for electrochemical energy storage.

Dr Liu and Dr Lin Gu from the Institute of Physics of the Chinese Academy of Sciences, as well as Dr Xinhui Xia from the School of Materials Science and Engineering of Zhejiang University, are the corresponding authors of the paper. Postdoctoral Fellow Dr He Zhu, who is also from CityU’s Department of Physics is one of the co-first authors of the paper.

A series of papers focusing on anode materials published

To further improve the performance of related materials, Dr Liu and other researchers continued their efforts in research. They discovered that by combining ion doping of chromium and spiral array architecture of TNO nanoparticles, intrinsic electronic and ionic conductivity were enhanced, resulting a more open TNO crystal structure with faster ion transfer paths. Also, with enhanced intrinsic electronic conductivity and reinforced structural stability, the material exhibited superior high-power performance with a large capacity and superior durability.

Their findings were published in the scientific journal Advanced Functional Materials, titled “Synergy of Ion Doping and Spiral Array Architecture on Ti2Nb10O29: A New Way to Achieve High‐Power Electrode”. Dr Liu is one of the corresponding authors of the paper and Dr Zhu is one of the co-first authors.

Moreover, Dr Liu collaborated with researchers including Professor Chengchao Li from Guangdong University of Technology in designing a solution combustion method, which could synthesize Nb 14W3O44, a micro-size niobium-based anode material. When compared with the conventional nano-sizing approach, micro-scale electrode materials have greater potential to be commercialised. Experiment results showed that the material exhibited excellent durability and the capability of fast charging and discharging. The team fabricated a full cell incorporating Nb14W3O44 as anode material and the commercialized LiFePO4 as cathode material. Such a battery showed a long durability of over 1000 cycles.

Their findings were published in the scientific journal Advanced Materials, titled “Achieving Ultrahigh‐Rate and High‐Safety Li+ Storage Based on Interconnected Tunnel Structure in Micro‐Size Niobium Tungsten Oxides”. Dr Liu and Professor Li are the corresponding authors of the paper and Dr Zhu is one of the co-first authors.

Cathode materials have greater commercial value

Dr Liu is an expert in lithium battery materials and has published about 30 papers since 2018. Although the three researches mentioned above are all about anode materials, Dr Liu also specialises in cathode materials. He once worked with Huawei in increasing the capacity of lithium cobalt oxide, the most commonly used and commercialised material in lithium batteries. He described the collaboration with Huawei as “of very high commercial value” because “cathode materials are much more useful in making batteries." He is currently working on the following three materials: nickel-rich ternary cathode material, lithium-rich manganese-based cathode material, and high-voltage lithium cobalt oxide cathode materials, hoping to achieve significant results soon.

This research article originated from CityU Research Stories.