Membrane distillation (MD) for wastewater treatment and resource recovery

We have been conducting research on a wide variety of membrane distillation (MD) applications with the goal of gaining a fundamental understanding of its vapor transportation mechanism in conjunction with membrane wetting and fouling behaviours. We are focused on the development of novel membrane materials and module designs for use in membrane distillation processes.

With industry support, we are now upscaling MD for the treatment of textile wastewater, which highlights two of MD’s notable advantages over conventional methods. Firstly, the project explored MD’s potential for using waste heat, enhancing MD’s energy efficiency and reducing costs. Secondly, the recovery and reuse of permeate water generated by the MD process for washing and reuse in internal production lines was explored, again underlining the positive environmental impact and cost efficiency of the MD process for the textile industry as well as MD’s potential feasibility for zero liquid discharge.

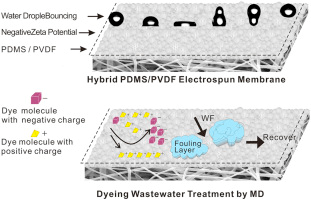

Dr. Alicia An and her group developed a hybrid polydimethylsiloxane (PDMS) polymeric microspheres-PVDF superhydrophic membrane via electrospinning. The membrane exhibited antifouling characteristic when treating differently-charged dyes wastewater. Such ideal membrane can be applied in Membrane Distillation for wastewater treatment.

http://www6.cityu.edu.hk/see/research/findings/alicia.htm

Seawater desalination using membrane technology

Reverse osmosis (RO), Membrane distillation (MD), Forward Osmosis (FO), and Hybrid Process

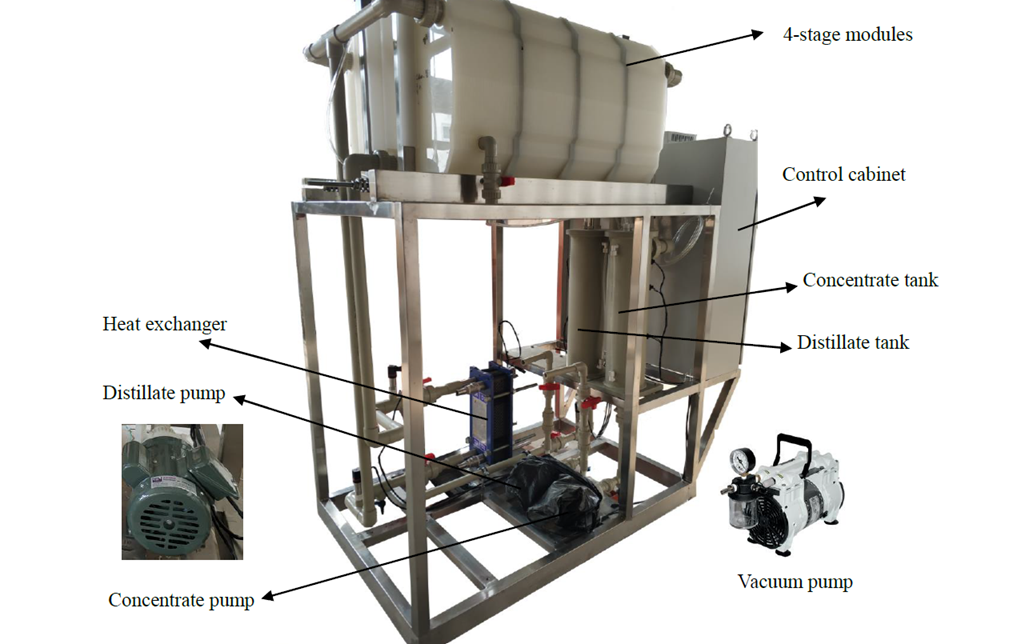

Our group is working on Desalination as a sustainable water resource based on emerging membrane technologies such MD, FO, and hybrid process with RO. Moreover, we are striving to achieve the concept of resource recovery from brine produced from desalination processes. Our team has proposed a novel membrane distillation-crystallizer (MDCr) for achieving energy efficient desalination and resource recovery. Below is a picture which illustrates the prototype crystallizer which has been developed as part of our Innovation and Technology Fund (ITF) project.

Prototype of the proposed membrane distillation-crystallizer

Prototype of the proposed membrane distillation-crystallizer

Membrane fabrication and characterization

Our group’s research interest lies primarily in the fabrication and practical applications of advanced polymeric membranes for use in water treatment, wastewater reclamation and desalination applications. In our lab, we use different techniques including phase inversion, interfacial polymerization, surface coating, track-etching, electrospinning etc. to develop advanced organic, inorganic, and nano-enabled polymeric membranes for nearly each membrane-based process (microfiltration, ultrafiltration, nanofiltration, reverse/forward osmosis and membrane distillation). Intriguingly, our in-house fabricated membranes presented practical solutions for preventing membrane fouling while retaining salts, heavy metals, and various organic micropollutants.

|

|

| Film applicator (Elcometer 4340) | Electrospinner, ET-2535 Beijing Ucalery Technology and Development Co., Ltd |

|

|

| Drop Shape Analyzer for contact angle measurements and surface free energy calculation with High Resolution and High-Speed Camera -DSA25S, KRÜSS GmbH | Capillary flow porometer, Porolux 1000, Germany |

Optical Coherence Tomography (OCT), GANYMEDE-II OCT system

Optical Coherence Tomography (OCT), GANYMEDE-II OCT system

Emerging membrane fabrication and application

One of our forward-looking research interests is to utilize solar energy in water treatment to make this process readily available for developing countries/regions with abundant solar irradiation. To accomplish such a goal, we aim to adopt the photothermal effect to membrane distillation processes. Heat created by photothermal materials can drive water vapor across the membrane requiring less electricity to be used. Carbon-based materials, which are non-toxic and cost effective, are chosen as the light-to-heat convertor. We fabricate nanostructured carbon materials with enhanced light absorbing ability, weakened thermal conductivity and porous network for vapor channels to achieve highly efficient distillation to produce clean water..